Introduction

The rule of “Two is one, one is none” applies to almost all preparations. But what happens if once we’re safely in our shelter, we discover we’re missing a tool?

In a WTSHTF situation, with no way to go out to a hardware store or have an online store deliver it to your doorstep, this situation would be catastrophic unless you had basic tools and knew how to build your own.

With makeshift materials (as some military manuals call them) when there isn’t anything else suitable available, you can build a tool for yourself that will do the job.

Available steel and ideal steel

To build basic open-ended wrenches, I have found that the best steel to use is the rear suspension leaf spring of truck, and that is often SAE 5160 steel. But it has drawbacks. In order to work with this steel, it is necessary to heat it in a forge and let it cool before using abrasive tools.

Some things are impossible when you are in your survival shelter and bug out, and don’t have a fully equipped workshop. So I used common 1045 steel, which was mild steel that is easier to work with hand tools. Those were what I had available at the time.

The American Society for Testing and Materials (ASTM) is the oldest entity that dictates standards for steel. It was founded in 1898 by a group of 70 engineers led by Charles Dudley. Although the ASTM is much older, it is not as well-known as the Society of Automotive Engineers (SAE). The SAE has the most widely-used standards. Anyone who wants to know more about these different standards can do some research on their own. That would be too much to discuss in this short article.

What Is steel?

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to pure iron. The main goals in formulating steel are strength and ductility. While there are some specialized steels that have up to 2 percent carbon content, they are the exception. Generally, steel used in making tools is under 1 percent carbon and often it contains less than 0.35 percent. Why? Because if steel exceeds 1 percent then it often becomes something akin to cast iron, which does not have the mechanical properties of steel, the most important of which is its lack of resistance to impacts. If a piece of cast iron is hit with a hammer, then it can break.

Classifications of Steel

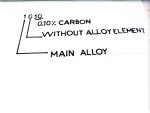

The most common steel classification standard is SAE, even in Latin America.

Steels are classified with numbers from 1 to 9, showing the percentage of carbon, which is shown in the last two figures. For tool making, this never exceeds 1% carbon.

Manufacturing Wrenches

Let’s say that you need to manufacture a 7/16″ open-ended wrench, because you don’t have a wrench of that particular size. First, a cardboard template is made with the corresponding measurements, taken from a similar tool. Then the silhouette is transferred to the sheet or scrap steel to match the silhouette, using is scribe.

With the basic data and in the corresponding table, we can choose the right machine tools that we need. In my case, I chose a 3/8″ drill bit. The next larger one in my drill register is 7/16″. But the hole we drill will not have the dimension we need for our rough cut, whether we use a drill measured in millimeters or inches. (You may recall in my previous article on chainsaw sharpening files, we used the 5/16″ and 7/32″ round files.) Until we reach the correct dimensions, it is acceptable to use undersized measurements for whatever we are building. We then very slowly file the steel to reach a precise fit.

Use The Correct Cutting Speed

Something that is often not taken into account is the speed of the drill bit, which is related to its diameter and the type of material to be drilled. This is recommended, as well as lubrication to prevent heating and breakage of the drill bit. If a suitable lubrication oil is not available, then lard is a very suitable lubricant for this purpose.

The most common drill bits are High Speed Steel (HSS), Cobalt, or Titanium.

A modern drill press allows you to adjust the number of revolutions per minute. To find the right speed setting for the drill bit, you can perform a simple calculation, shown here in metric figures:

RPM = Cutting speed ×1000 / drill bit diameter × π

For a HSS drill, a cutting speed of 25 m/ sec is adopted.

RPM = 25 m/sec ×1000 /9 mm × 3.14

RPM = 884.64

Not all drill presses can be set to match the number of revolutions that we calculate, so a lower number is always used. In my case, I was able to set my drill press to 550 RPM. If you use a higher number of revolutions, then it will almost surely damage the drill bit.

Bibliography

American Machinists Handbook and Dictionary of Shop Terms, by Colvin, Fred and Stanley, Frank, 1914.

MÁQUINAS by A.L. Casillas, 1984 (in Spanish, my native language)

JWR Adds: One of my favorite introductory books on this subject is The Making Of Tools by Alexander G. Weygers

Read the full article here