A paradox that faces the American shooting public is that some of the most popular chamberings are typically not built to match standards. By far, the lion’s share of .223 Rem., 5.56 NATO and 9 mm Luger is created for casual plinking or training on larger, short-range targets. Those looking to apply such cartridges to precision applications typically need to make a significant investment in ultra-premium specialty ammunition, which, for reasons of cost, limits the amount of training that can be conducted.

For those reasons and more, father and son Jeffrey and Jordan Low, with backgrounds in business and military service, respectively, were inspired to found a component factory that could help shooters achieve match-grade results without the associated exorbitant expense. The plan was simple: Build everything from scratch and inspect as frequently as the machinery allowed. This mindset would become the basis for First Breach, an ammunition and component manufacturer conceived in 2018 and named for Jordan’s former Israeli military unit, the Golani Brigade.

With a rough sketch of what had to be done, the team needed a place to get started. New factories are typically best drawn from existing factories, particularly ones with defense-related experience. After sitting dormant for more than 34 years, Fairchild Aviation’s defunct production plant in Hagerstown, Md., rose to the top of the pair’s list of candidates and, just two years later, was reborn in the same spirit of American support, precision and craftsmanship.

The geographical and historical significance of this site simply cannot be overlooked. This facility represents the first major expansion of one of this country’s most prominent aeronautical pioneers. It also sits adjacent to the borders of Pennsylvania and West Virginia, effectively contributing to the economic growth of three different states. The factory had produced several iconic aircraft, however, the most instantly recognizable of these is likely the A-10 Thunderbolt II, better known as the Warthog. This close-support attack aircraft is as much a flying gun as it is a plane, as the airframe was designed specifically to support the GAU-8 Avenger 30 mm autocannon. Watching these aerial vehicles work is awe-inspiring, and setting up shop in their former birthplace left some big shoes to fill.

Getting the factory back online involved a Herculean effort, as time alone had been enough to deteriorate the structure. As the Lows told us the story of the plant’s restoration, I was impressed to find out that, joined by their VP of operations, Benjiman Donivan, and general plant manager, Michael Fuentes, the team took a predominant role in not only the design but the manual labor as well. In my experience, when a team contributes literal blood, sweat and tears to a project, the outcome is usually phenomenal. As the factory was built in the 1940s, extensive updates were required to the electrical and plumbing systems, as well as a complete overhaul of the compressed-air arrangement. This included the addition of 12 new transformers to make use of the existing 7,900-amp substation.

The company’s initial U.S.-made ammunition products include match loads in .223 Rem. and 9 mm Luger.

With the plant now ready to receive production equipment, the founders of First Breach searched the globe for the best that money could buy. Unfortunately, the best that was out there was still not up to the rigorous standards they demanded. With that, a secondary project began: the development of a full-service machine shop. The plan here was to install the machines that would put them closest to their goals, only to tear out the critical wear components and re-install versions that are made from better materials and even tighter tolerances. Entire pneumatic systems and bushings were overhauled and strengthened, enhancing the machines’ reliability and precision. Having such capabilities also ensured the company would never have to halt a machine due to parts unavailability, which plays a significant role in cost reduction, as it eliminates the potential for the company to be paying personnel to merely come in and babysit inoperable equipment.

First Breach quickly learned the importance of having full control, which only furthered its efforts to build from the ground up. As the early plan was only to support the current ammunition industry through components, production began with simple copper and brass cups. The brass of choice is a 70/30 alloy of copper and zinc, making it the most ductile of all the brass variants on the market. This allows it to be more easily drawn into cartridge cases, thus making them inherently more uniform. Bullet jackets are crafted from a 90/10 alloy of copper and nickel, which carries the same benefits as the brass but is ultimately softer. The components are induction annealed several times throughout the process to eliminate the effects of work-hardening and ensure uniform expansion when subjected to the heat and pressure of firing. Induction annealing is a state-of-the-art process that is relatively new to the ammunition industry. Instead of producing heat through burning gases, it uses high-voltage magnetic friction to heat-treat the brass. This allows it to hold a more consistent temperature and offers the ability to fine-tune the operation.

Although First Breach operates as a full-scale ammunition plant, the company plans to stay true to its roots by offering components, such as bullets (l.) and cases (r.), so that reloaders can assemble their own recipes.

This same mindset is carried over to bullet cores, which most don’t consider to be as critical as a case or jacket. Smelting its own lead and drawing it into wire is the only way First Breach sees fit. As this facility is one of the newest in the world, it was refreshing to see that this portion of the plant was walled off and is serviced with a separate ventilation system. All staff involved in this process are trained, fitted and supplied with a personal respiration system, and their blood is tested for lead levels on a quarterly basis. Such care for the employees’ health and safety is admirable.

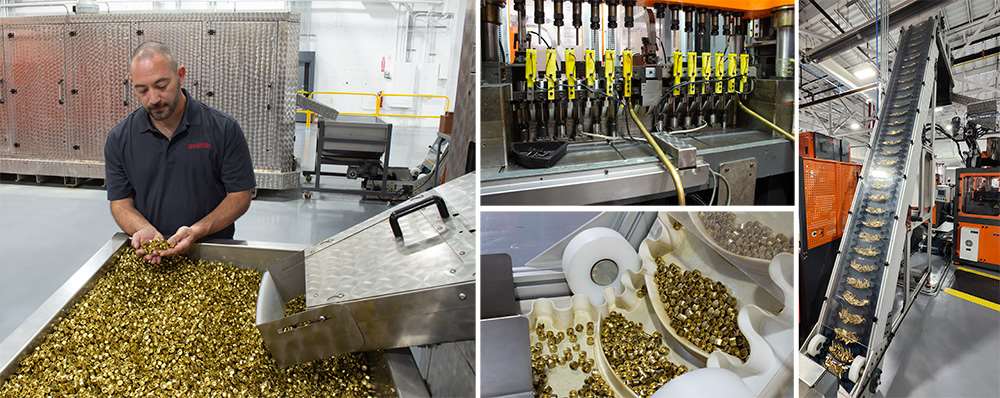

Scoopfuls of component copper jackets, primer cups, cases and lead bullet cores (opposite, l. to r.) await further manufacturing steps and eventual assembly into complete cartridges.

It didn’t take long until the team realized it ought to press these components together, so the company immediately expanded into complete bullet production. This is an ambitious venture, as entire companies exist for that process alone, and it requires an entirely different skill set. First Breach was able to reverse-engineer proven designs and hold them to higher standards. This nearly eliminated the entire cost of research and development, leaving more money on the table to upgrade quality controls. By applying the same “make best better” principle to its inspection machines, it modified a match-grade grain scale to achieve a rejection value of a scant three-tenths of a grain. The inspection process before that point is equally impressive and combines cutting-edge technology with good, old American craftsmanship. First, machine operators hand-inspect a sample from each lot with “go” and “no-go” gauges to ensure the size and shape of the given projectile are where they are supposed to be. From there, 100 percent of the projectiles are sent to a computerized measuring apparatus that uses a laser micrometer to scan the bullet from every angle. This is aided by 8K-resolution cameras that detect imperfections that are nearly undetectable by the human eye. Most impressive of all is that the components that became these bullets are also treated in a similar way long before they reach this point.

With excellent bullets and brass on hand, the can-do attitude brought the company to full-scale ammunition production. This aspect might just be my favorite part of the entire story, as it exemplifies the American dream and shows us just how far a simple notion can take you. Keep in mind that the sole idea for First Breach was to create improved copper and brass cups that would allow other ammunition companies to make better ammunition. So what started as a dinner-table conversation ended up as an entirely new manufacturer located in one of the country’s most storied factories, making match-grade rifle and pistol loads.

First Breach re-engineered, and continuously inspects, its loading equipment (r.) to ensure consistency in component manufacture, and even its 5.56 NATO offering is loaded to match specifications, which is atypical. The author (above) gets hands on the brass cups from which cases are drawn.

Although the company name is a nod to Jordan’s military service, little did the father and son know that cup production would also be the first breach into cracking the ammunition-production barrier. This facet of the business is kept rather close to the vest, and I cannot divulge the powders, primers or loading processes the company employs, but I can note that the inspection process is ruthless and is only complete after each round passes through human hands. Evaluating a sample of the 124-grain 9 mm Luger through a 4.2″-barreled FN Edge pistol at 25 yards, I can attest that these efforts did bear quality fruit. Not only did it prove to be reliable, but the load grouped tighter than most ammunition in its class, generating 1,065 f.p.s. and 312 ft.-lbs. of muzzle energy and printing five, five-shot groups that averaged 2.65″, with the smallest group measuring 2.12″ and the largest 3.14″.

Our tour ended with a discussion of First Breach’s future. Several major manufacturers have requested more of their products, and First Breach is eager to satisfy them. As it does indeed continue to fill the role of ammunition-industry support, another cup-production line is in the works to increase this output. With another 116,000 sq. ft. of the factory ready to come online in 2025, plans to expand every other operation are already being executed as well. Most exciting to the industry is likely the dedication of 60,000 sq. ft. to primer production, which is set to commence production this year as well. This flow of high-quality components into the manufacturing vessel will enhance the products of every brand they touch, not to mention establish a new source of all-American loaded ammunition. The news is so exciting that one local technical school is in talks with First Breach about starting an internship program for its machining and engineering students.

Each round of the company’s main offerings—9 mm Luger and 5.56 NATO— is hand-inspected to ensure its consistency.

The last topic we discussed before departing First Breach was its plans to expand the current catalog. Ammunition and components for 9 mm Luger and 5.56 NATO/.223 Rem. are a great place to start—the company currently offers the former in 115-grain and 124-grain FMJ loads and the latter in 55-grain FMJs for each—but where should it go from there? Without surprise, the answer included many of the other most popular cartridges in this country, as well as those in other countries around the world. This is thanks to several international certifications for which the company has recently received approval.

Talks of common NATO and Warsaw Pact cartridges piqued my interest, and I left the facility wondering which specific products were next for the company. After my tour and discussions with its leadership, I realized that, whatever they are, they will doubtless yield top-tier results while retaining bargain-basement price tags.

Read the full article here