The Ruger Security-Six, Police Service-Six and Speed-Six double-action revolvers, introduced in 1970 and produced through 1988, innovated in design and construction in such ways as to challenge that period’s status quo regarding the modern wheelgun’s strength and simplicity.

The company’s first double-action swing-out-cylinder revolver design, the series made extensive use of chrome-moly and stainless-steel investment castings, employing a solid frame that allowed for easy fieldstripping since it dispensed with the more typical sideplate-style construction that persists to this day. The common six-shot frame size made for a series of revolver that were not only sturdy but trim.

Chamberings, depending on model, included .357 Mag., .38 Spl. and 9 mm Luger, being differentiated primarily by sight arrangement and butt shape—the Security-Six featuring a fully adjustable rear sight and “square” butt and the square-butt Service-Six and round-butt Speed-Six having a fixed rear sight consisting of a channel cut in the topstrap. Barrel lengths included 2¾”, 4″ and 6″, and versions were available in both blued and brushed-stainless finishes. Weights ranged from approximately 31 ozs. to 36 ozs. and overall lengths from 7¾” to 11¼” depending on barrel length and configuration.

The basic design is credited to Ruger engineer Harry Sefried working with company founder Bill Ruger, and it relied heavily on the latter’s penchant for coil springs and his then young company’s casting expertise. The frame, crane, hammer, trigger, trigger guard and several smaller parts were produced from chrome-moly castings with the barrel being machined from a forging that incorporated the raised sight rib and ejector rod housing.

Ruger literature on the Security-Six at its introduction stated: “It is a handsome, rugged holster revolver—compact in the overall, yet massive enough to properly be designated as a heavy-duty revolver for the rigors of police and military service.” That final claim likely related to the series’ unique facility for disassembly with nothing more than a cartridge rim or coin, which is why the screw that holds the stocks in place has a wide slot. Further, it is the only threaded fastener present in the gun except for windage and elevation screws in those models with the adjustable rear sight.

The fire-control mechanism featured a transfer-bar safety in which the hammer nose rested on the frame, and the transfer bar did not align with the firing pin until the trigger was fully to the rear. Also, the hammer could not be cocked when the cylinder had been swung out, and the cylinder could not be opened when the hammer was cocked.

The cylinder assembly was released to swing out to the left by depressing the cylinder-release button in the left recoil shield of the frame. The hammer spur of the Security-Six revolver was checkered sharply to provide good purchase, and examples of the Speed-Six have been encountered with “bobbed” hammers that either bore checkering at their top front, allowing for single-action fire, or that were smooth and allowed only double-action fire.

Lockup of the Security-Six and its stablemates was by way of an auxiliary spring-backed front latch in the barrel assembly that engages a detent in the front end of the ejector rod. Smartly pressing the ejector rod to the rear effected simultaneous ejection of fired cases or cartridges from the cylinder, and retraction of the ejector assembly into the cylinder was automatically accomplished by a spring when the ejector rod was released. The individual chambers did not have rim counterbores except in 9 mm Luger-chambered models.

American Rifleman Technical Editor M.D. Waite, in his original Dope Bag review (May 1971, p. 24), wrote: “Overall precision of this revolver is very good, and its general pointing and handling qualities are excellent. As might be expected, this medium-weight gun is not pleasant to shoot with .357 Magnum service loads. However, despite the relatively small grip and arched backstrap, recoil is not unduly punishing provided the gun is gripped tightly to restrain its recoil. The high placement of the cylinder-release button makes it unlikely that it will strike the shooter’s thumb as the gun recoils.”

The following year, Associate Technical Editor Ludwig Olson summed up his Exploded View treatment of the Security-Six (June 1972, p. 60) with these words: “Handling and pointing qualities of this well-made, reliable revolver are excellent, and its overall precision is very good. Its double-action trigger pull is satisfactorily smooth, without excessive buildup of resistance when the trigger pressure is increased. The single-action pull weighs approximately 3 lbs., and has very little creep.” Waite also had the foresight to observe: “Overall quality of machine work and finish of the Security-Six revolver furnished The American Rifleman Technical Staff are very good. It is a fair prediction that this gun will be well received in the marketplace.”

While the Six series was, indeed, well-received, its lifespan overlapped that period of time when police departments began transitioning to semi-automatic pistols, which meant that its days as a service revolver were numbered. Superseded by the similar, but somewhat larger GP100, the Six series was nonetheless a staple in the Ruger catalog for nearly two decades and rode on the hips of law-enforcement officers and even some military users both domestically and abroad for years afterward.

In sum, the Sixes made their mark by being innovative, mechanically strong and aesthetically pleasing, and many owners still consider them to be unsurpassed for their unique combination of compactness, durability and utility, with rare military and commemorative examples commanding a premium on today’s used market.

click here for enlargement

Disassembly Instructions

No special tools are required to fieldstrip the Security-Six revolver to component groups and parts shown. First, verify that it is unloaded and then close the cylinder. With a cartridge case rim or a screwdriver, unscrew stock panel screw (48) and remove both stocks, exposing the mainspring (44) (Fig. 1).

After removing disassembly pin (43) from hollow stock panel dowel in frame, cock hammer (24), insert disassembly pin half its length into hole in mainspring strut (19), pull trigger and then lift mainspring assembly out of frame (Fig. 2).

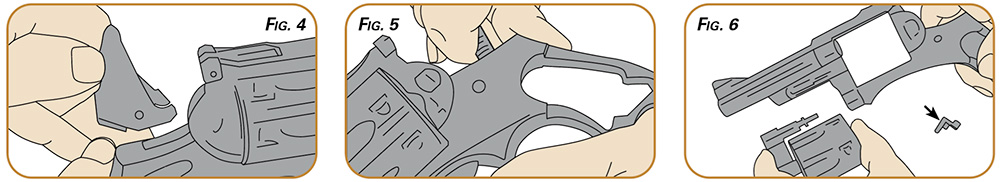

While holding trigger back, push exposed end of hammer pivot pin (20) in left side of frame with fingernail and withdraw pin from right side (Fig. 3), then lift hammer up and out of frame (Fig. 4).

To detach trigger guard from frame, use mainspring strut assembly to depress trigger guard lock plunger inside frame at rear of trigger guard. Simultaneously, pull down rear end of guard assembly and withdraw it from frame (Fig. 5).

To complete field disassembly, remove cylinder latch (38, arrow) from bottom of frame and withdraw cylinder assembly forward and out of frame (Fig. 6).

Further disassembly of the gun for routine maintenance is neither required nor recommended.

Reverse the above procedure to reassemble the revolver.

Read the full article here